Rich power offers good quality porcelain insulator in a lower price and good services. All products meet the requirement of the standards of IEC, IEEE, DIN, BS, EN, and ANSI. OEM production is accepted. All products will not deliver until they pass the inspections. We have a complete test equipments with a complete test processes.

There are different types of insulators according to different materials as follows:

- Porcelain Insulator: (based on ceramic material i.e. china clay, quarts, aluminum silicate, plastic kaolin, feldspar)

- Glass Insulator: based on toughened glass having high dielectric strength up to 140kV/cm.

- Steatite Insulator: bases on magnesium silicate (different % of magnesium oxide + silica).

- Polymer Insulator: based on fiberglass and epoxy polymer.

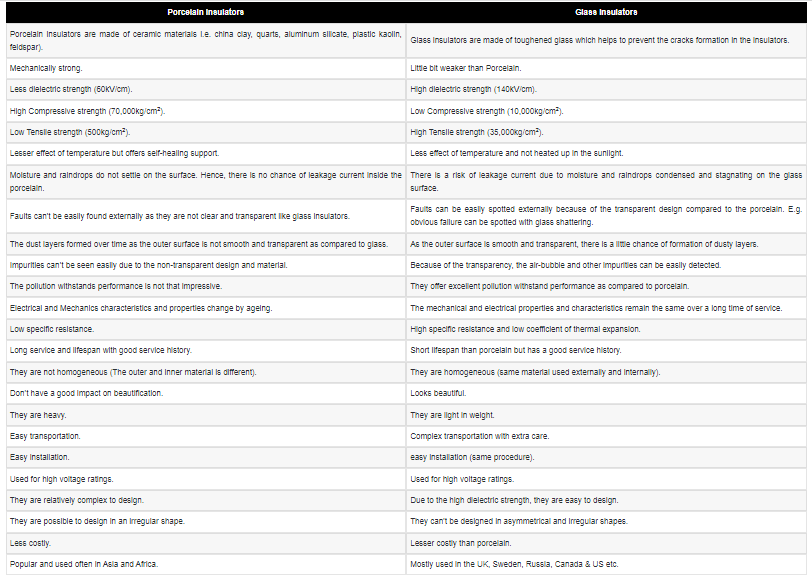

What is the differnce between glass and porcelain insulators?

The suitable material to achieve the above properties are; toughened glass, glazed porcelain, and composite polymer. The toughened glass is obtained by rapidly cooling the glass insulator after shaping and allowing the interior to cool slowly. In this way, the glass insulator has the outer surface in compression and the inner surface is in tension.

glass insulator:

Glass insulators offers a compressive strength and tensile strength of 10,000kg/cm2 and 35,000kg/cm2 respectively.

Annealed glass material is used for insulators and it is useful in transmission and distribution systems. The glass is cheaper than porcelain. The dielectric strength of glass is 140 kV/cm and it is more than porcelain. It has high resistivity and a low coefficient of thermal expansion.

Mostly the glass used as an insulator is transparent. Therefore, the impurities or air bubbles can be easily detected, and also, it is not heated up from sunlight like porcelain. But the disadvantage of a glass insulator is that the moisture can condense the glass surface and provide a path to the leakage current.

Porcelain Insulator:

Porcelain is a ceramic material and a good ceramic is free of internal densities, holes and cracks formation without thermal expansion.

Now porcelain is the most commonly used material to make insulators for an overhead transmission line. Porcelain does not allow to pass electric charge and it works efficiently when it is combined with other non-conductive materials. It is aluminum silicate mixed with quartz, feldspar, and plastic kaolin. This results in hard and glazed material that is ideal for an insulator.

A strong porcelain insulator has a dielectric strength of 60kV/cm, compressive strength of 70,000 kg/cm2 and tensile strength about 500 kg/cm2.

Cement is used as bonding material to make the porcelain insulators which is one of the most popular types of insulators used widely around the world in power transmission and destruction networks.

Rich power offers porcelain insulators according to the standards of IEC, BS, DIN, EN, ANSI, etc. OEM production is accepted. All products of ours have lower price and good quality.

The following comparable table shows the main features, characteristic and properties of both porcelain insulators and glass insulators which shows the key differences between them.